THE MOST RELIABLE SOLUTION FOR HEAVY DUTY TAPE FOR ROPE, TWINES, CABLE FILLER AND OTHER INDUSTRIAL APPLICATION

SIMA extrusion line Techno Tape-Rope is the most advanced technological solution in the field of fibrillated and not fibrillated PP and HDPE tapes production, designed for the fabrication of twisted rope, braided rope, fishing nets, baler twine, cable filler and other industrial applications. SIMA extrusion lines respect SIMA policy which is environment-friendly, i.e. oriented towards energy-saving in terms of design and new solutions, thus not affecting the performances of the equipment.

The line is conceived to offer the customers the optimum combination of quality and flexibility. This process, starting from the raw material to the packed and palletized finished spool, can reach a linear production speed beyond 300 m/l’.The extrusion line Technorope ensures with the smallest investment compared with its high productivity, to cover the requirements of many market sectors, maintaining at the same time a high level of reliability and efficiency, not to mention the top quality of the finished product. The SIMA Technorope extrusion line is the most flexible rope-making line, at the forefront of the world market, and no doubt meeting the most sophisticated requirements of all customers.

HOPPER FEEDING – EXTRUSION – SPINNING: THE BIRTH OF THE PRODUCT

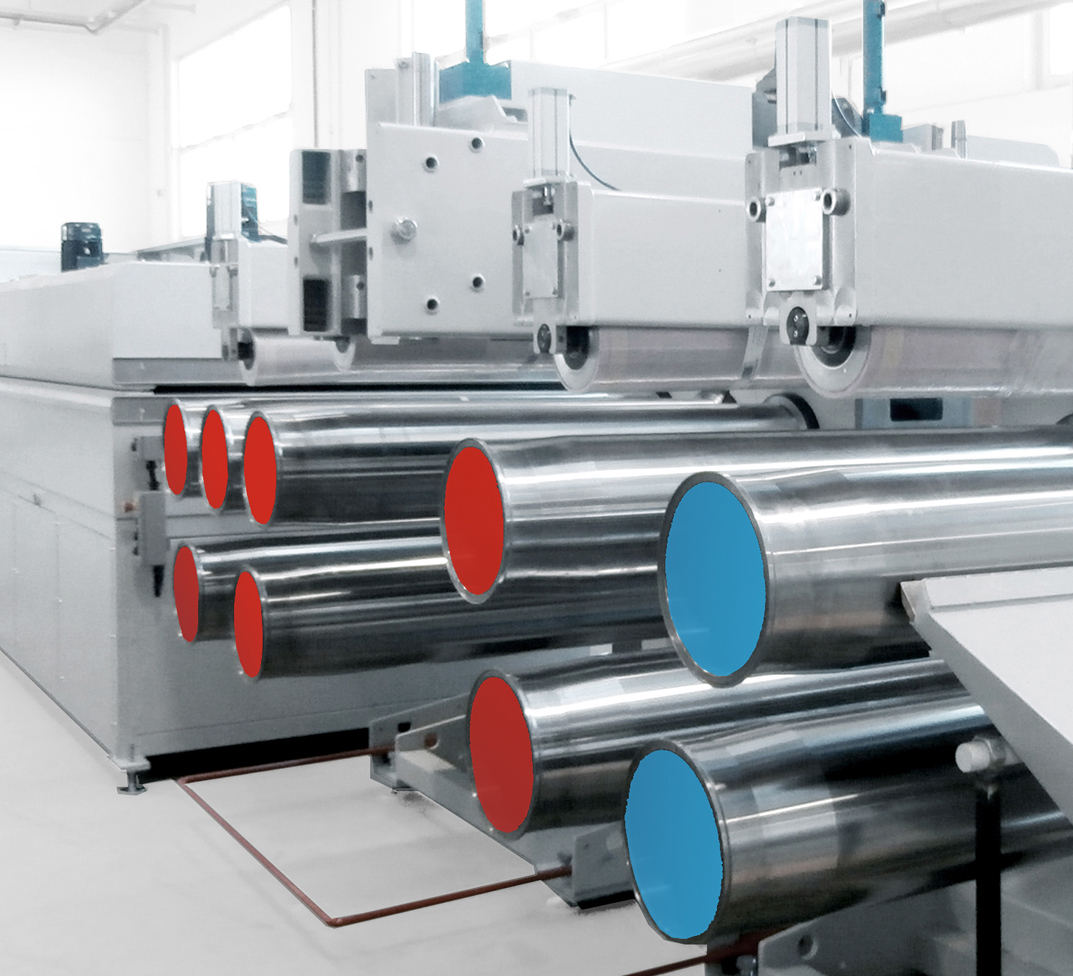

MOLECULAR ORIENTATION OF THE PRODUCT

STABILIZATION PROCESS OF THE PRODUCT

Thanks to performing annealing process, elimination of internal tension are granted, which helps to obtain a uniformly oriented product free of localized memories, controlled elongation and stability of the product. All this allows to work in line with downstream equipment without shrinkage problems of the final product.

THE FIBRILLATION PROCESS

The extrusion line Techno Tape-Rope is totally computer controlled, thus guaranteeing

RELATED PRODUCTS

Here’s a quick list of all Sima Ds related products you could be interested in.