TWO-FOR-ONE TWISTER WINDER

The GS2000-E is the last generation of SIMA twister winder, designed under the two-for-one-twist principle for the production of twisted yarns and twines using natural and/or synthetic fibers in the range of 5,000 – 120,000 deniers.

The externally strong mono-block frame is well balanced and operates vibration free.

The covers assure low noise level, due to their high noise-proof efficiency and in accordance with the most rigid standards

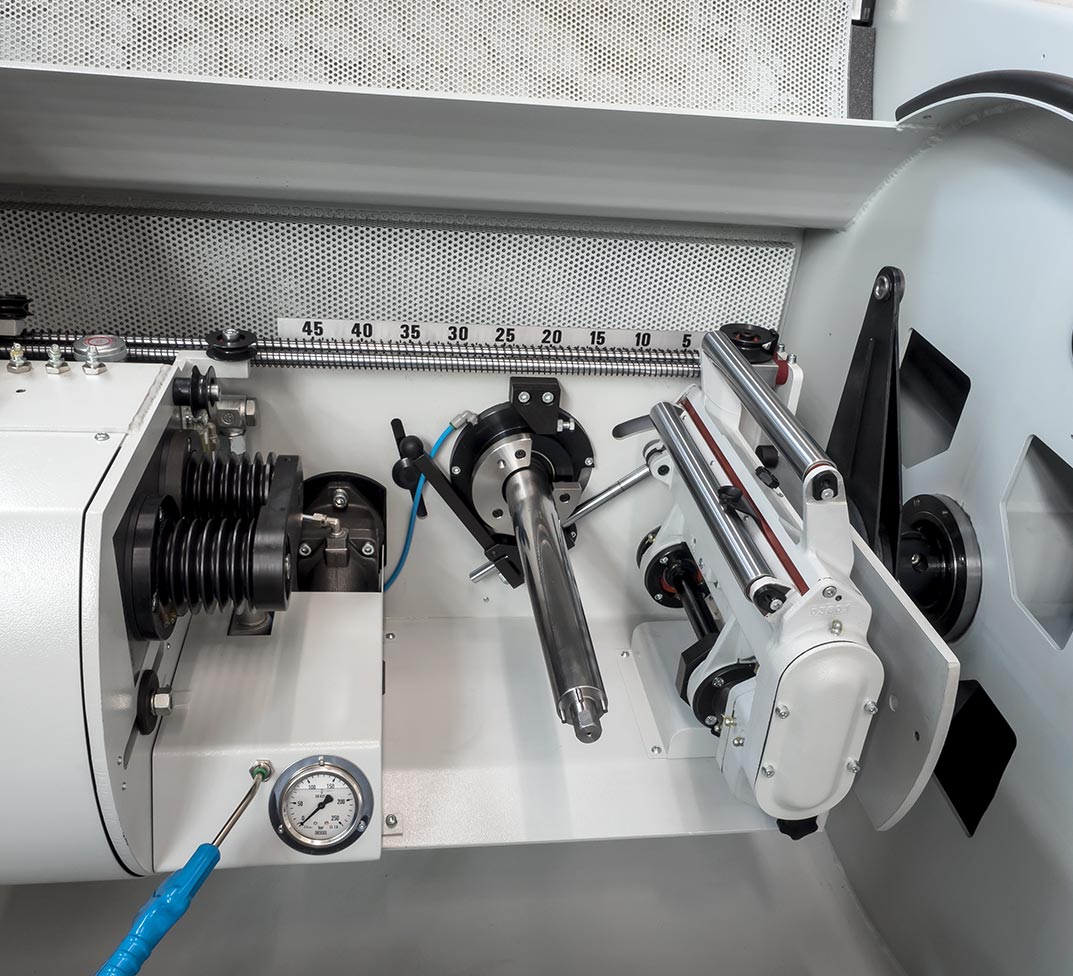

All moving parts have been studied for optimal ease of operation allowing the GS 2000-E to operate at 3.500 rpm, with a standard production capacity of 7000 twists per minute and with a special version for light deniers up to 4000 rpm and 8000 twists per minute.

Thanks to new specially treated materials, the friction coefficient has been reduced to a minimum, allowing a constant specific tenacity of the yarn during the twisting process.

Starting from yarn spools or bobbins , this machine is suitable for making spool from min. 4”x4” to max. 12”x12”, equipped with main A.C. driving motors, with mandrel – multiple type for the production of spools with tube – expansion type with link rods for spools without tube.

Screw boxes are available from 4” to 12” traverse.

The machine can be combined with AC2000 accumulator to work in line directly from extrusion line for monofilaments, cable filler and twine production.

The GS2000-E can be also used as take-up unit of Rope Layer Mod 200/4.

The main features of the machine are:

RELATED PRODUCTS

Here’s a quick list of all Sima Ds related products you could be interested in.